Many farmers prefer to use whole milk to feed their calves. Some find it more convenient, others believe it to be a more natural product that is best suited to the calf – nature’s original liquid feed strategy.

Whole milk can exist in a number of forms, each with a different potential impact on health, performance and convenience. Issues can include:

- Inconsistency of quality and availability

- Transmission of pathogens and disease

- Antimicrobial resistance

Energized Calf Milk (ECM) has been developed with whole milk as the biological reference, mixing the best of whole milk with the best of CMR.

Just like milk: naturally high energy

Inspired by saleable milk, ECM is high in fat ensuring the calf gets a high level of energy. The balance of vitamins and minerals within the formulation means that the calves get the best possible LifeStart. Farmers should soon see the difference in calf performance and appearance.

Biosecurity: the high cost of disease

Mortality and morbidity take a surprisingly high toll on some farms due to:

Contamination

Waste milk carries a risk of microbial contamination from E. coli, bovine viral diarrhoea virus, Listeria monocytogenes and various species of Streptococcus, Salmonella, Mycoplasma, Campylobacter and Staphylococcus, as well as possible transmission of diseases such as Johne's (Selim and Cullor, 1997; Stewart et al., 2005).

Saleable Milk: maximising returns

For economic and traditional reasons, the use of the variations of whole milk remains widespread on farms. However, as an increasing number of producers evolve towards more modern standards of health and performance they are looking for all the benefits of whole milk feeding with the added consistency of a manufactured product.

ECM allows the farmer to maximise returns for the business by selling that milk, rather than using it on farm.

Antimicrobial resistance (AMR)

Antibiotic traces in waste milk have been shown to contribute to resistance (Langford et al., 2003; Hinton, 1986; Teale et al., 1999; Khachatyran et al., 2006).

The consistency of manufacture of ECM supports safe feeding every time giving you peace of mind.

Manufacturing: focus on consistent quality

The specialised raw materials for ECM are produced by Trouw Nutrition. The process begins by mixing the fresh dairy products with vegetable oils and fats. This mix is pasteurised and then high-pressure homogenised and spray-dried, utilizing advanced technology. This results in miniscule fat globules of uniform size, similar to the small fat molecules in cow's milk.

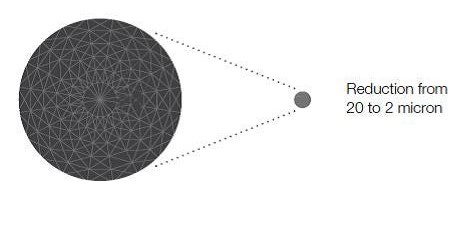

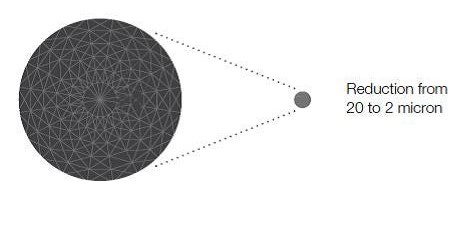

Homogenisation

Creates an optimal fat globule size, similar to cows' milk, for improved solubility and stability in solution.

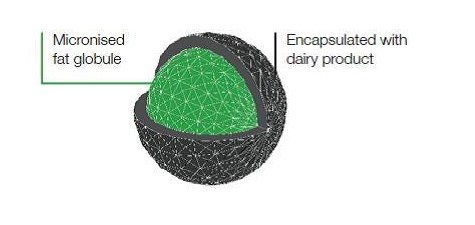

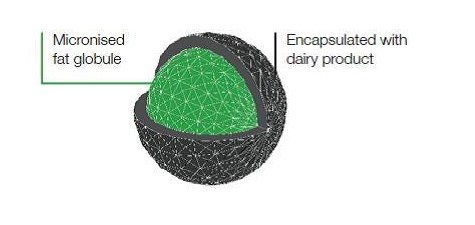

Encapsulation

The micronised fat globules are encapsulated with dairy products to improve the absorption and increase intake.

Contact us

Our team of experts are always on hand to help you out with any advice you may need.